Professional FPGA chip solution provider

- Wide Product Range

- Competitive Pricing

- Global Service

Wide Star Electronics

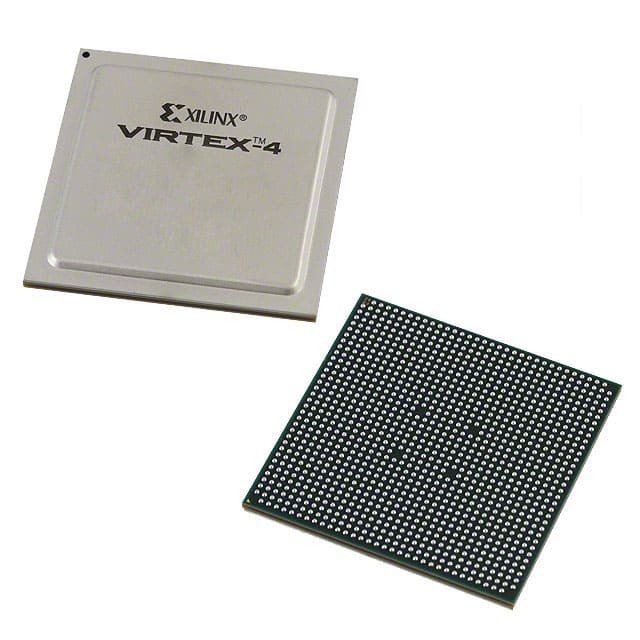

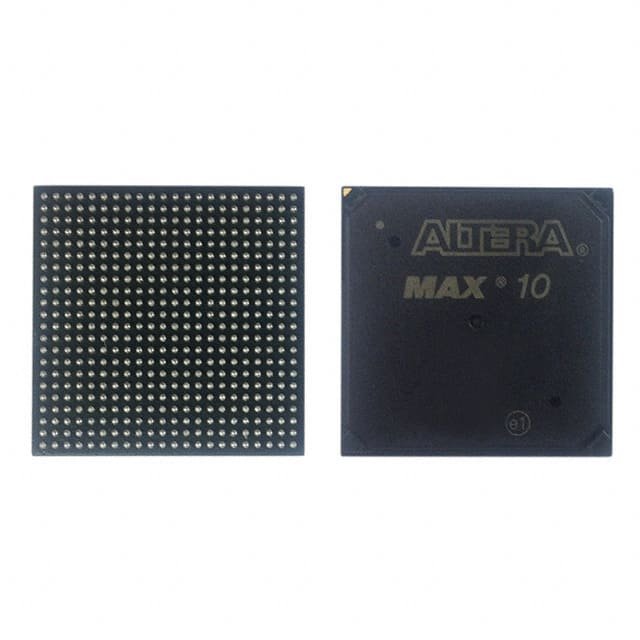

Popular FPGA chip display

At Wide Star Electronics, located in the heart of Wuhan’s high-tech district, we are renowned as a leading independent distributor of active IC brand lines. We serve OEM and EMS companies worldwide, offering a broad range of electronic components. Our extensive inventory includes some of the most sought-after FPGA chips in the industry, designed to meet diverse application needs in sectors such as AI, consumer electronics, and computer peripherals.

Ensuring Timely and Safe Delivery

More Than Just an FPGA Chip Exporter

At Wide Star Electronics, our expertise extends beyond the mere export of FPGA chips. We understand the critical importance of managing electronic components supply chains effectively. Therefore, we provide customized solutions that address excess inventory management, helping to alleviate component allocation challenges and assisting in sourcing discontinued and obsolete parts.

We offer immediate purchasing options to meet your urgent component needs, ensuring you have access to essential parts without delay.

Our strategies help optimize your procurement process, reducing expenses while maintaining quality and reliability.

We manage and liquidate excess or idle inventory, turning potential financial burdens into opportunities for profit and reuse.

We provide complete support for your bill of materials, ensuring all necessary components are bundled effectively for your projects.

Our value-added services include detailed component testing, secure packaging solutions, and logistical support tailored to your specific requirements.

Quality Assurance

Our Commitment to Unmatched Quality

At Wide Star Electronics, established in 2003, we don’t just distribute IC components; we ensure each piece surpasses industry standards for our global partners in Europe, North America, and Asia. Explore our exhaustive quality assurance measures:

External Visual & X-ray Inspection

Baking & Function Testing

Solderability & Decapsulation Tests

Comprehensive Electrical Performance Evaluation

Environmental Compliance: Lead-Free & RoHS Testing

Heated Chemical Durability Assessment

Frequently Asked Questions About Wide Star Electronics

Wide Star Electronics offers a diverse range of electronic components, including AI, consumer electronics, computers and their peripherals, communications, industrial control, automotive electronics, security, power supplies, instrumentation, new energy, and medical equipment. We cater to a broad spectrum of industry needs.

Yes, we specialize in handling large-scale orders and have a stable supply chain capable of meeting the demands of mid-sized OEM and EMS companies. Our business model is designed to provide reliable, quality components at competitive prices.

Quality is a cornerstone of our business. We conduct rigorous testing and quality checks, including external visual inspection, X-ray testing, baking tests, function testing, and more, to ensure that every product meets the highest standards.

We primarily export to Europe, North America, and Asia (excluding China). Our extensive logistics network allows us to deliver components efficiently and reliably across these regions.

Customers can place an order by contacting us directly via email at vip@widestarelec.com or by calling us at 027-86659956. Our team is ready to assist with any procurement requirements.

Wide Star Electronics stands out for its stable supply, reliable quality, reasonable pricing, and honest service. With over two decades of experience, we have established ourselves as a trusted partner in the electronic components distribution industry.

FPGA chip introduction

An FPGA, or Field-Programmable Gate Array, is a type of semiconductor device that can be programmed after manufacturing. It consists of a matrix of configurable logic blocks (CLBs) connected via programmable interconnects. This allows the FPGA to be customized to perform specific functions or tasks as required by different applications, making it highly versatile and adaptable.

FPGAs are particularly valuable in applications that require rapid prototyping and systems that need to be frequently updated or customized. They are used across various industries, including telecommunications, automotive, aerospace, and more, due to their flexibility and the efficiency they offer in implementing complex digital computations.

Delivery and Verification

The final step in ensuring the safe transportation of chips involves a thorough verification process upon delivery:

Upon arrival, it is crucial that the received shipments undergo a detailed inspection to check for any signs of tampering or damage during transit. This step ensures that all components have been delivered in the condition expected and are ready for use or further distribution.

Accompanying documentation should be checked to ensure compliance with shipping regulations and customer requirements. This includes verifying packing lists, purchase orders, and any customs documentation for international shipments.

Implementing a feedback mechanism is beneficial for continuous improvement. Recipients should have an easy way to report discrepancies or issues with the shipment. This feedback helps logistics providers and senders to refine their processes and enhance the overall safety of future shipments.

Once verified, chips should be promptly integrated into the recipient's inventory system. This integration helps in maintaining accurate stock levels and facilitates efficient tracking of components throughout their lifecycle in the supply chain.

Quality Assurance

ISO 9001:2016 Certified Quality Management

At widestarelec, we understand that quality is the foundation of trust in the electronic components industry. That’s why we are proud to be ISO 9001:2015 certified, demonstrating our commitment to consistent, high-quality operations across sourcing, warehousing, and customer service.

– ✅ Standardized processes to ensure full traceability

– ✅ Strict quality inspection to eliminate counterfeit or substandard products

– ✅ Improved delivery efficiency to meet peak-season demands

– ✅ Globally recognized certification to enhance your brand’s credibility